The R-type transformer is a rookie in dry-type transformer products.The core is made of high-quality oriented cold-rolled silicon steel coils of various widths and widths, and is made into a round shape.Moreover, the cross section is round and can be wound without cutting.Therefore, the transformer thus manufactured has no noise, small magnetic leakage, small no-load current, low iron loss, and high efficiency;And since the coil is cylindrical, the length of the copper wire per turn is short.Therefore, the internal resistance is small, the copper consumption is low, the temperature rise is low, and the overload fluctuation is small.Explosive better than the toroidal transformer;R-type transformers are becoming more and more popular in the electronics industry due to their novel and unique structure and excellent electromagnetic performance.Particularly suitable for medical equipment, display equipment, audio equipment, office equipment

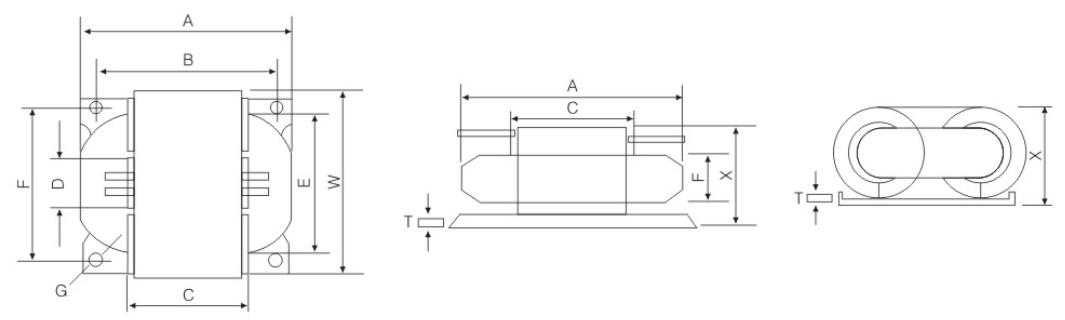

1. The electronic transformer of the R-type iron core structure is 30~40% smaller than the electronic transformer of the old structure.Light weight 40~50%, thin thickness 30~40%.Since the basic structure is mostly horizontal and side vertical,Therefore, this thinned electronic transformer is most suitable for modern high-density installation.2, no-load characteristics are good: 1 no-load current is small, smaller than 1/20 of the same-power C-type transformer;2. The no-load loss is small, which is smaller than 1/2 of the C-type transformer of the same power.

3. Since the cross section of the R-shaped iron core is circular, the magnetic field distribution around the iron core is the most uniform.In addition, the winding method of reverse-balanced R-core winding can effectively suppress the leakage flux in the middle of the two coils.Therefore, the leakage magnetic flux of such a transformer is extremely small, about 10% of the E-type transformer and 20% of the C-type transformer.

4. Since the R-shaped core is not cut, its iron loss is extremely small.It is only about 20% of the E-core structure and 50% of the C-core structure.5. Since the cross section of the R-shaped iron core is circular, the average winding length of the winding is 6~10% less.

5. Since the cross section of the R-shaped iron core is circular, the average winding length of the winding is 6~10% less.Use less barrels and lower copper loss; from another perspective,Since the magnetic flux density of the R-type core is as high as 19,000 Gs or more, the number of turns can be reduced.Thereby, the amount of copper used is further reduced, and the copper loss is reduced.

6. Since the R-type iron core is not cut, the electrical parameters of the transformer of the R-type iron core structure,The electrical performance is extremely consistent.

7. Since the R-type iron core is not cut, the electronic transformer of the R-type iron core structure has extremely low noise.Less than 10% of the C-type transformer.

8. The electronic transformer of the R-type iron core structure has excellent no-load characteristics.The efficiency is extremely high and the loss is extremely small, so the temperature rise is naturally extremely small.

9. The electronic transformer with R-type iron core structure is a veritable energy-saving product.It is a universally acknowledged fact.R-type electronic transformers have entered computers, copiers, printers, typewriters, copying machines, television cameras, radio and television transmitters, CNC machine tools, gourmet amplifiers, CRT monitors,Electronic medical equipment, precision testing equipment, automated instrumentation, satellite communication receivers, advanced chargers,High-precision inverters, robots, electronic control equipment, remote sensing devices, production lines, weaving equipmentSynthesizers, aerospace measuring instruments and other applications.

1, the inrush current of the R type transformer When the secondary of the transformer is open, the primary current has a transient impact process at the moment when the primary voltage is applied to the rated voltage.It is called the inrush current.The inrush current duration is very short, usually at 50 Hz.This current will last for 1/4~1/2 cycles, that is, 5ms~10ms, and then it will enter a steady state.Within a few milliseconds times the rated current of an insulating material and does not cause damage to the winding.

All R-type transformer inrush current characteristics of a relatively large, reducing the inrush current has the following methods:(1) It is possible to reduce the magnetic flux density Bm of the iron core and increase the number of primary winding turns W,The transformer reduces the saturation of the core when the no-load is closed, thereby reducing the inrush current.But the premise is that the power of the transformer is sacrificed.(2) The R-type transformer with higher power can reduce the inrush current by winding the primary winding around the outer layer and winding the secondary winding around the inner layer.

2. Protection of R type transformer

Transformer protection, overcurrent protection can be divided into short circuit protection and overload protection.The fuse can only serve as a short circuit protection, for the impact problem,The fuse used in the primary of the transformer can be a time-delay fuse, or its rated current can be taken from 3 to 3.5 times the rated current of the transformer.